CURRENT TREATMENTS 2016

McKay Lodge mentioned in Smithsonian Science News regarding the conservation of outdoor sculptures by Luis Jiménez.

“VAQUERO” Luis Jiménez

Smithsonian Museum of American Art, Washington, DC.

“SODBUSTER” Luis Jiménez

Plains Art Museum, Fargo, ND.

TREATMENT OF “LOS LAGARTOS”

Luis Jiménez

City of El Paso, TX.

Leading automotive finishes company PPG Industries has enthusiastically joined with McKay Lodge Conservation Laboratory, Inc. of Oberlin, Ohio in establishing new methods and applications of their most advanced finishing materials for repairing weathered outdoor sculptures by Luis A. Jiménez.

The southwest artist Jiménez famously painted his colorful glass fiber and resin sculptures with automotive paints, finishing with an automotive clear coating. Many such works placed outdoors have deteriorated, requiring repaintings and recoatings by the artist and by others. Several of these “restorations” have also failed. Typically, deteriorations are in the form of cracking, disbonding of the clear coat(s) and fading of the colors. The artist Luis A. Jiménez died on June 13, 2006.

Drawing from the huge array of coatings products PPG designs and makes for various vehicle performance requirements, including trucks, buses, aircraft and personal vehicles, the PPG technical team members are selecting the color base coatings and various clear coatings they feel will achieve the strongest bonding and longest coating life in high heat and bright sun environments as well as protection from abuse and vandalism.

The PPG technical team has been given corporate permission to devote time and resources toward working with McKay Lodge, Inc. conservators in product use training, in selecting the best materials and advising on best practices to achieve the highest level of durability and protection possible for the painted works of Jiménez.

PPG has been working out critically important, multi-stage treatment procedures involving existing clear coat overall reduction and surface preparation, a primer stage (for repaired damaged areas), intermediary clear coat, color base, a secondary application of an intermediary clear coating, and a final top clear coat. In addition, PPG puts emphasis on, and is selecting coatings for, the interior surfaces of the moisture permeable glass fiber and resin bodies to significantly prolong the life of the paints and exterior clear coats.

A new top clear coat for Jiménez sculptures will be the most critical component for protecting the surfaces and colors of the artworks. PPG has made significant advancements in coating technology in the last few years with the newer coatings outperforming the older technologies by a wide margin. The coatings chosen by the PPG technical team represents PPG’s latest advance in fleet coatings technology. The premium PPG coatings were designed to provide resistance to sunlight, extreme temperatures, abrasion, graffiti and a wide range of fluids and chemicals.

It seems that only with the superior products and technical expertise of a company like PPG can the many deteriorated works by Luis Jiménez be restored and preserved.

Restoration work is currently underway at the McKay Lodge, Inc. sculpture facility on the Jiménez sculpture SOD BUSTER from Fargo, North Dakota. Conservation work has been completed on LOS GARTOS, El Paso, Texas and on VAQUERO from the Smithsonian Museum of American Art, Washington, DC. The condition of MUSTANG at the Denver International Airport has been assessed. Upcoming projects will include FIESTA JARABE from the Otay Mesa Border Station near San Diego, California and EAGLE at the Nerman Museum, Kansas City, Missouri.

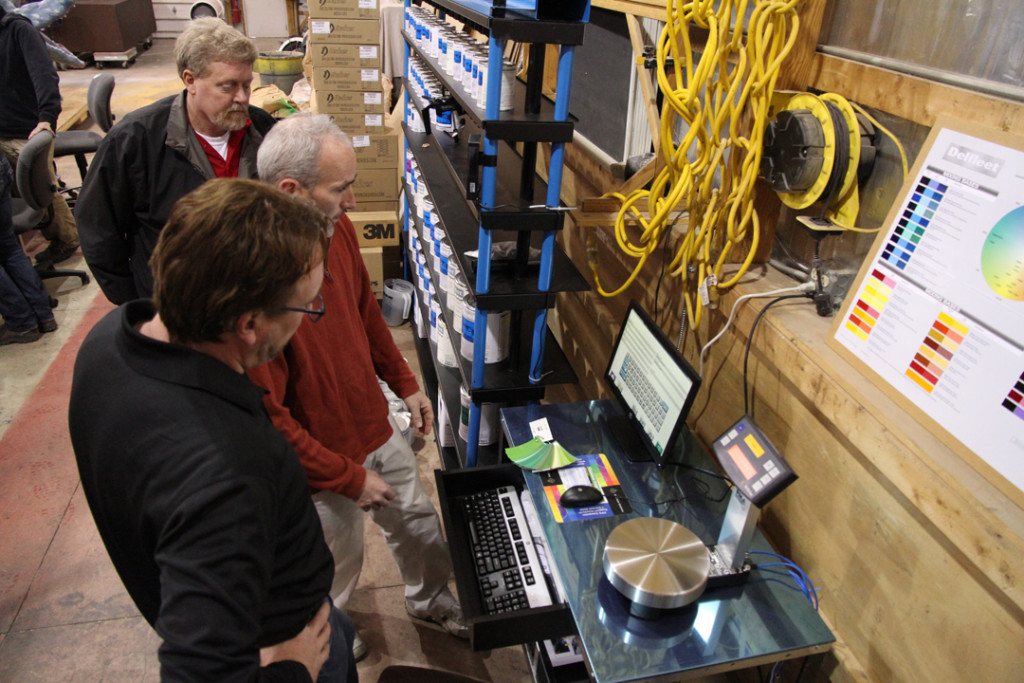

PPG has installed at the sculpture conservation facility an advanced color products bank and computer controlled weighing and mixing station for precision matching of original colors, including pearlescents, in small touch-up batches. Work on LOS LAGARTOS was completed by August 2014. The sculpture’s ability to resist fading and clear coat failure under the intense El Paso sun is now greatly enhanced.

OTHER SCULPTURES BY LUIS JIMÉNEZ: PROGRESS OF THE WORK ON LOS LAGARTOS

OCTOBER 24, 2013

Introduction:

For this project (our third working with sculpture by Luis A. Jimenez) we advanced the state of materials and techniques applied to the repair of damages and deterioration of the FRP (fiber-reinforced polymer) and automotive finishing products used together to create the art work LOS LAGARTOS.

Specifically, we brought to the project the very latest of advanced products and methodologies used in the automotive finishing industry including products specific to high value FRP automobile bodies.

The intention of the research and testing was not only to provide a more lasting refinishing of the Jimenez sculpture, but to enable us to more effectively repair damages such as cracks, ongoing disbonding, and losses on a smaller, more local scale, avoiding as far as possible covering original paint in good condition. In addition, it was clear to us that the conservation treatment of LOS LAGARTOS would become a model for needed treatments of other sculptures by Jimenez exposed to the outdoors.

We were greatly aided by the interest and direct involvement in this project by numerous technical specialists from the PPG Automotive Refinishing Division, the world’s leader in this technology. The level of their interest and willingness to devote time to this one project, including visits to our facility surprised us. PPG technical experts developed product selections for the conservation treatment, particularly the new clear coat, from the many of their products available for that application.

Work to-Date:

- The sculpture was delivered and offloaded by our crane and operator. It was unwrapped and placed into our shop.

- Soils and heavy accumulations of minerals were removed for a good view of the colors and surfaces.

- Images of the work before its past “restoration” (which included local spray repainting by Jimenez) were compared with the current surfaces to see if the original colors, or the new paint applied locally by the artist, had faded. This also enabled us to differentiate much of the artist’s later paint applications from his initial painting. Reportedly no clear coat had been applied at its past restoration but one was clearly present and the PPG experts confirmed this.

- All instances of clear coat delamination, damages from impacts, cracks, evident areas of earlier damages and deteriorations since covered by the local repainting of the artist, and the artist’s obvious repainting were digitally documented.

- Telephone consultations with PPG technical personnel for updated advice on automotive color and clear coatings and auto-body repair techniques with the many new, advanced PPG materials caught the interest of PPG. An on-site review by PPG automotive technical consultants was held at the sculpture at our facility. This visit further interested PPG and additional PPG technical expertise flew in to meet with the first team at our facility for further discussion. At this second meeting the group of conservators and PPG technical expertise worked out procedures and optimal new, advanced automotive materials for the repair of this art work, and potentially other outdoor works by Luis Jimenez in the future.

- Areas of intense technical focus by PPG technical consultants and McKay Lodge, Inc. conservators were: (a) water migration through FRP and the optimal interior coatings against this; repair of cracks; (b) sealing cracks against moisture infiltration; (c) removal of disbonded clear coat; (d) optimal filling materials; (e) optimal base color system products; (f) optimal timing of curing of coatings for adhesion; (g) optimal preparation of the existing clear coating for bonding of a final new clear coating; (h) necessary shop environmental conditions (temperature and humidity) for optimal performance of new advanced PPG automotive materials; (i) and a color mixing station to be set up at out facility for rapid color adjustments to match the artist’s local color adjustments.

- PPG approved of the clear coating reduction methodology we developed from our extensive experience with fine abrasive media and air/abrasive delivery tools.

In addition, PPG continued to have interest and support of this project and throughout the process consulted with others at the PPG automotive group to finalize the restoration products and procedures; and made themselves available at our facility for hands-on guidance and advice with use of some of their latest and advanced products.

The next visit by PPG expertise delivered the color matching instruments, a computer controlled color mixing station and base colors.

NOVEMBER 22, 2013

Technical Meeting with PPG Industries and Spray Finishing Suppliers:

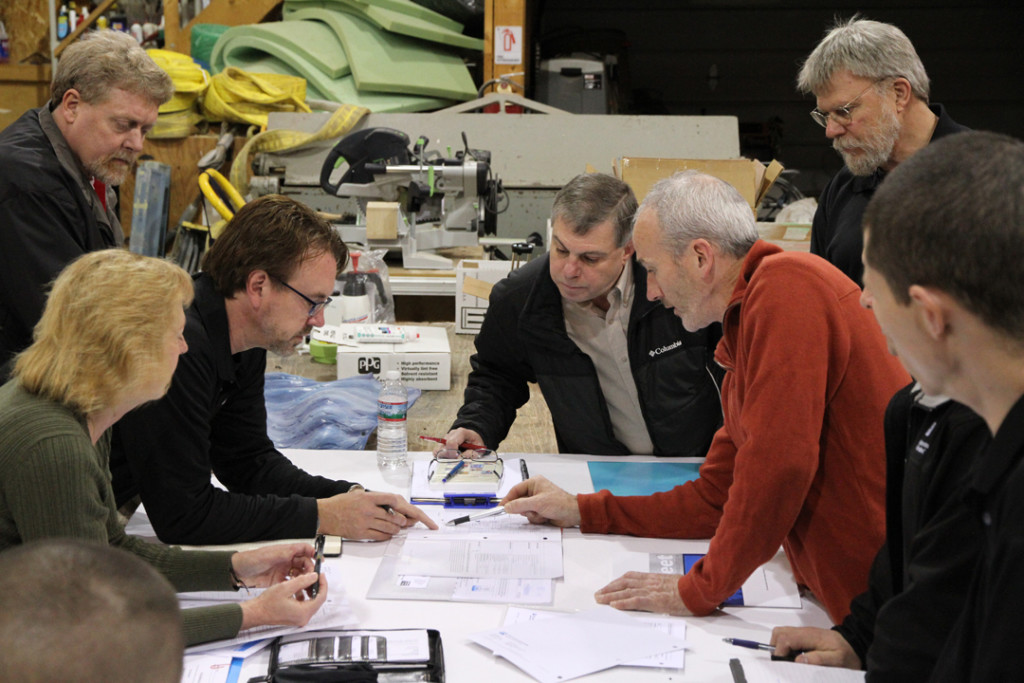

November 21, 2013: A technical meeting and training session was held at McKay Lodge Conservation Laboratory, Inc. to discuss PPG’s materials recommendations for restoring Jimenez sculptures and to train in new PPG products’ critical and somewhat complex color mixing and applications procedures.

Attending:

Kathi Minut PPG Territory Manager

Brian Nowak PPG Commercial Territory Manager

Jamie Redd PPG Technical Sales Instructor Supervisor

Gregg Whitmer PPG Zone Business Development Manager

Pat Berg Painters Supply Co. Technical Representative

Mike Springer Painters Supply Co. Territory Manager

Jim Gwinner McKay Lodge, Inc. Jimenez Project Sculpture Conservator

Emmett Lodge McKay Lodge, Inc. NACE Certified Coatings Inspector

Robert Lodge McKay Lodge, Inc. Conservator of Modern Sculpture

The world’s leading automotive finishes company, PPG, showed increased interest and support in working with McKay Lodge, Inc. conservators toward finding the optimal methods and materials for restoring and preserving the outdoor painted sculptures of Luis A. Jimenez, both in general and specifically for restoring and protecting LOS LAGARTOS from El Paso, Texas now undergoing treatment at the McKay Lodge, Inc. painted sculpture facility.

Drawing from the huge array of PPG’s coatings products for the performance requirements of various vehicles, including trucks, buses, aircraft and personal vehicles, the PPG technical team selected the color base and various clear coatings they felt would achieve the strongest bonding and longest coating life in high heat and bright sun environments as well as protection from abuse and vandalism. The PPG technical team had been given corporate permission to devote time and resources toward selecting the best materials and advising on best practices to achieve the highest level of durability and protection possible for the painted works of Jimenez.

The system specified and presented at this technical and training meeting consisted of a 5 stage process; a primer stage (for repaired damaged areas), intermediary clear coat, color base, a secondary application of the intermediary clear coating, and a final top clear coat.

The new top clear coat was a critical component for protecting the surface and colors of the artwork. PPG had made significant advancements in coating technology with the newer coatings outperforming the older technologies by a wide margin. The coating chosen by the PPG technical team represented PPG’s latest advance in fleet coatings technology. This premium coating was designed to provide resistance to sunlight, extreme temperatures, abrasion, graffiti and a wide range of fluids and chemicals.

The PPG team inspected the reduction of the old, failing clear coat Jim Gwinner achieved with air abrasives and approved its state for the start of surface repairs. As soon as all the materials PPG specified for this project were gathered, the surface work resumed.

JUNE 23, 2014

Continued Removal of Disbonded Coatings:

Further reduction of the clear coating was obtained with the use of dry ice (CO2) blasting. This extremely gentle method of removal was found to be effective at removing the many small areas of disbonded top coating without damage to the paint layer underneath. Dry ice blasting works because of three primary factors: kinetic effect, thermal effect and sublimation. The results were reviewed by PPG technical consultants and in their opinion it achieved a good base for bonding of the additional paints and clear coatings.

The kinetic effect occurs when dry ice pellets are accelerated by compressed air to high speeds, fracturing the top layer of the coating. The dry ice pellets are non-abrasive, nonconductive and disappear on contact.

The thermal effect occurs once the dry ice impacts the coating. The temperature of both the containment layer and the substrate decreases. The different materials contract unequally and the adherence between them decreases.

Sublimation occurs after the dry ice makes its initial impact and instantaneously turns from a solid to a gas. The volume expansion (by a factor of 700) causes a micro explosion that detaches the coating from the sculpture.

This method was quite effective at further removing the damaged/disbonded or weakened top coating.

Interior Coating:

Once the dry ice blasting was complete, treatment to the inside of the sculpture was performed. This included cleaning of the interior with high pressure water and then coating the entire interior with a high solids two part industrial epoxy. The epoxy coating was impermeable to water, and effectively sealed the interior of the sculpture, preventing any water migration from damaging the coatings. PPG strongly recommended the sealing of the interior surfaces, principally because moisture can travel along glass fiber and resin interfaces and cause deterioration of the exterior surface coatings. This ill-effect was first discovered by PPG to have occurred on FRP (fiber-reinforced polymer) Corvette hoods.

Repairs and Fills:

Once the sculpture had received the epoxy coating on the interior, the exterior work began. This included repairs to the losses and cracks of fiberglass structure. Any stress fractures were opened up and filled with a flexible two part urethane from 3M (3M SMC/FRP repair. This two part urethane remains somewhat flexible to allow for movement in the sculpture and should keep the fractures from re-occurring.

Recoating:

The first stage of recoating the sculpture began once the surface repairs were completed. The PPG-recommended specifications entailed a four stage process, starting with (1) the application of an “intermediate” process clear coat (to protect the original color base), followed by (2) the color or base coating (touchup), and then (3) reapplication of the clear coating (to protect the newly applied color) followed eventually by (4) a final clear coat.

SEPTEMBER 3, 2014

Final Clear Coating:

The treatment concluded with the spray application of a durable clear coating for outdoor exposure.

The project continued to benefit from the materials selection, applications recommendations and on-site presence of PPG company technical expertise. Following PPG’s selection for the color coatings and intermediate clear coatings, PPG selected its most durable clear coating for the final protective. Their selection is the toughest and longest lasting clear coating in PPG’s product line. This coating is used in commercial fleet finishing for vehicles such as chemical trucks and buses. The coating has no known end of protective service life. PPG recommends that waxing is not needed. There is no predictable need for replacement.

Final surface preparation of the treated sculpture with its lightfast base colors was performed according to PPG’s specifications and readiness to receive the final clear coating was inspected and approved by the PPG technical team.

The spray applications (two coats) of the clear coating was performed on Friday, August 29, 2014. The applications by Jim Gwinner, considered to be tricky and requiring experience with this particular product, were guided and supervised by the following PPG technical experts:

Jamie Redd

National Fleet Refinishing Trainer

PPG Automotive Refinish Division

Columbus, Ohio

Gregg Whitmer

Zone Manager

Refinish Training

Strongsville, Ohio

The final clear coat application process was recorded in video.

The finished sculpture was placed outdoors on Tuesday, September 2, 2014 to await return to El Paso, Texas.

Maintenance:

According to PPG, the surface of the sculpture requires no maintenance other than washing to remove soiling as needed. Waxing should not be performed. The clear coating has no known end of service life. The coating is chemical resistant so most forms of graffiti may safely be removed with solvents (always test, however).

Acknowledgements:

We express our grateful appreciation to the PPG company and its automotive and fleet coatings technical team for their essential involvement in this art conservation treatment and for the provision of a PPG mixing station essential for the accurate utilization of PPG advanced products.

UPCOMING TREATMENTS ON SCULPTURES BY LUIS JIMÉNEZ

“SODBUSTER”

Plains Art Museum, Fargo, ND.

“VAQUERO”

Smithsonian Museum of American Art, Washington, DC.