1943 German 88mm PAK 43/41 Anti-Tank Gun

Military Artifact Conservation

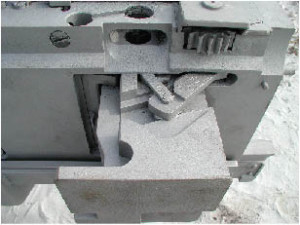

Free-Up Recoil Spades for Deployment:

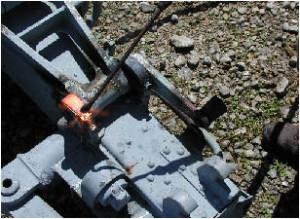

The pivot shaft of each recoil spade was immovable from corrosion. Repeated work with heat, chilling and penetrants could not free them.

Eventually, the steel bands holding the eccentric pivot shafts of the recoil spades had to be cut. The cuts can be seen in the top of each band. This allowed some expansion. Then a hole was drilled into each pivot shaft cover to allow penetrant to reach the inside of each eccentric.

After disassembly, cleaning of the shafts and eccentrics, the assembly operated smoothly. The cuts and the holes in the shaft were then welded closed.

Recoating:

All steel was blasted to white metal with powdered and crushed glass according to needs.

The new coatings on the gun follow the original color sequence: red lead primer, Dunkel Gelb, then Oliv Grun. This would allow authentic appearance at areas of wear, revealing the two undercolors.

The sliding breach block, permanently corroded in place and impossible to remove, was left unpainted and was polished to simulate authentic wear. Its bare steel was protected with Ship-2-Shore corrosion control clear coating (see page 20).

Application of the first coat of PPG Keeler & Long Kolorpoxy tinted to match a red lead primer.

Application of a second coat of PPG Keeler & Long Kolorpoxy tinted to match Dunkel gelb.

Application of the first of two coats of PPG Keeler & Long Polysilicone Alkyd flat enamel tinted to match original Oliv Grun found on the gun.

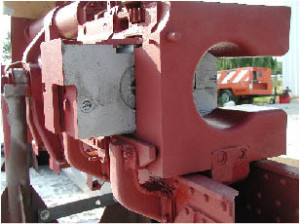

Reassembly after component painting with Oliv Grun.

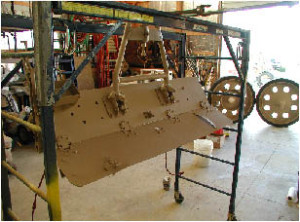

Recoil Beam Cover:

The gun’s recoil beam had two protective, sliding steel covers to keep water and debris from falling into the “U” shaped beam. Despite these covers, rain water had been entering and filling the inside of the beam. These covers were removed, corrosion was removed from inside of the beam, the inside was thoroughly coated with Ship-2-Shore corrosion control coating (see page 20), the open areas of the beams were then fitted with 5 mil Mylar adhered with urethane caulk – completely sealing these spaces against infiltration by water, then the covers were replaced.